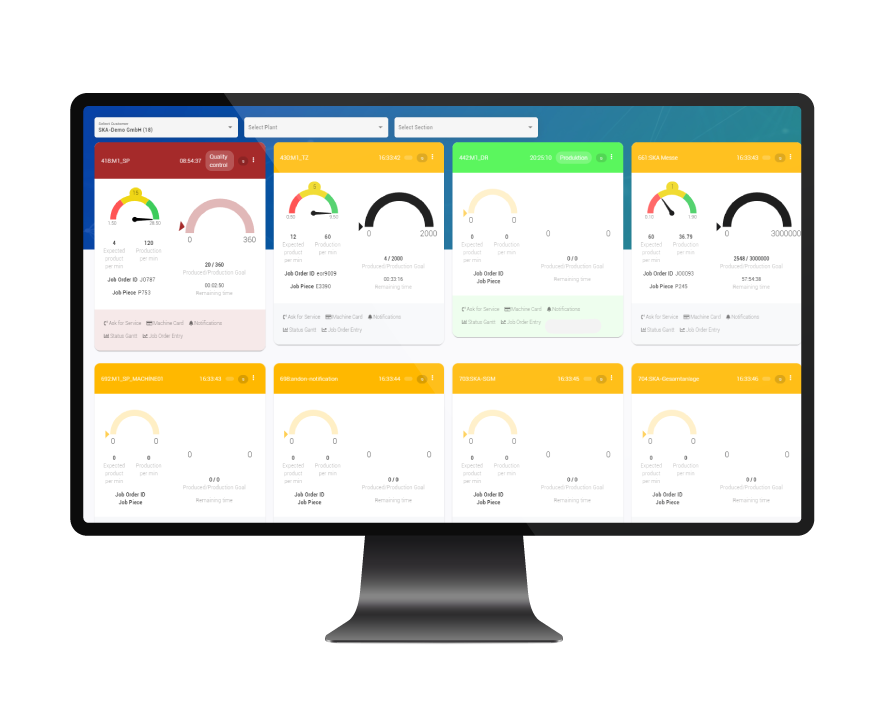

Gain new insights, solve complex problems, increase productivity and reduce costs in all your processes.

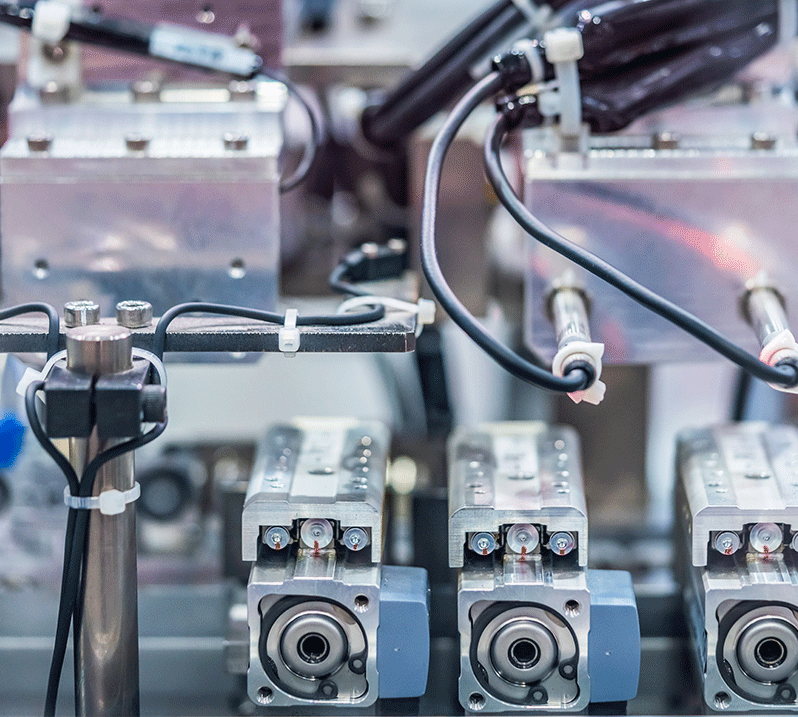

BILEN Analytica gives you the ability to remotely monitor, control and analyze your processes and energy consumption anytime. Sensors (Things) can be easily connected via plug and play to one closed cloud network.

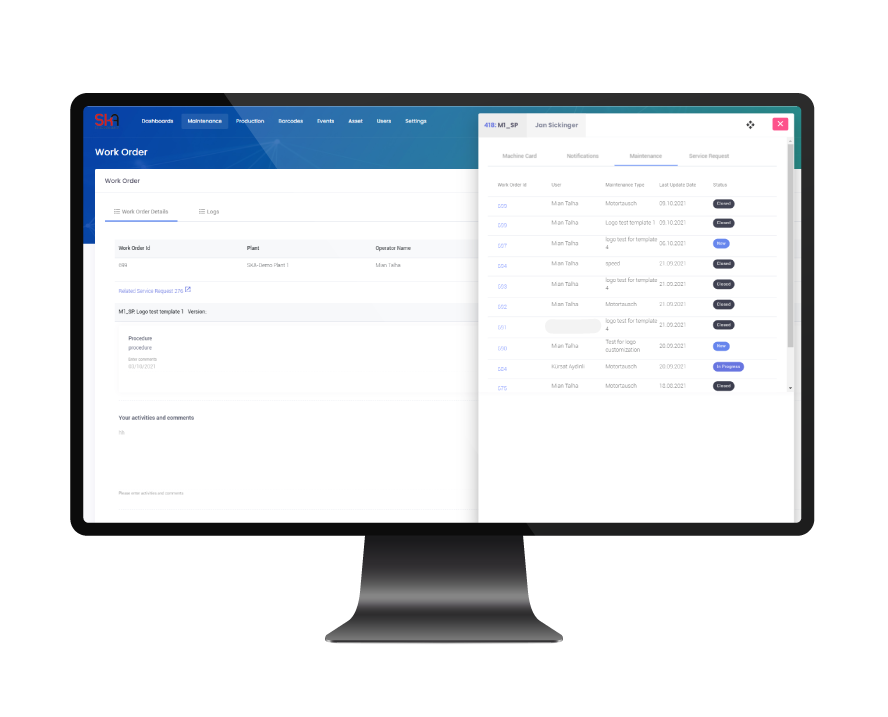

The integrated BILEN Cloud offers you a variety of further functions. From an alarm function in the event of a deviation to planning, documentation and management of activities (like maintenance services).

No more paper work. Everything is stored digital.

Request your first initial consulting session (free of charge) to discuss further steps.